CHANGES from 1.34 to 1.35 dated 13-05-2024

- Correct conversion calculation in case of pruning (and fall-down)

- Correct initialization of chicken weighers in case of fall-down

- Added 0-10V depressor flap operation

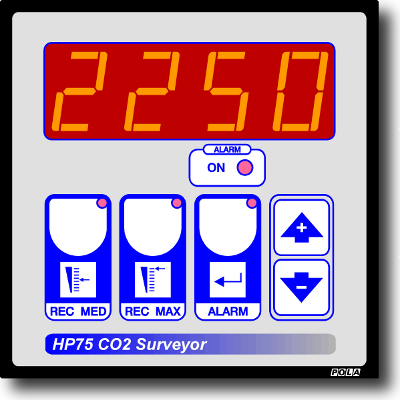

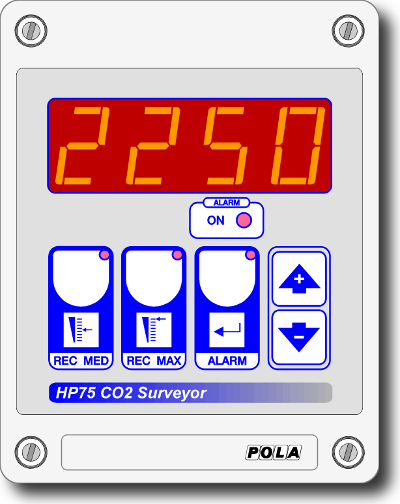

- Added all types of reading (4-20mA, 0-5V, 0-10V) for humidity, CO2 and NH3 probes

- Improved M3H operation (step transition from 0 to 1 with memo % active)

CHANGES from 1.33 to 1.34 dated 03-07-2023

- Fixed NH3 representation in last 48 hours archives

- Filtered NH3 reading to inhibit NH3D probe initialisation

- Locked in (E->2->4->H...) access to nest times if set independent from LAB

CHANGES from 1.32 to 1.33 dated 26-01-2023

- Corrected calculation of M3h variation for CO2, NH3, T.External and Temporary Variation

- Changed lights datatype (advance/lag) from mm:ss to hh:mm:ss

- Modified nest datatype (early/late) limit from 300' to 720'

- New independent nests function

- New aux 1 and 2 timer function

- Improved external humid climate management (possibility to set a negative delta)

- Improved nest relay management (1" wait on relay exchange)

- Improved 0-10v ventilation forcing management (active only if set for a time ->0v*1"+10v*T)

CHANGES from 1.32 to 1.33 dated 26-01-2023

- Corrected calculation of M3h variation for CO2, NH3, T.External and Temporary Variation

- Changed lights datatype (advance/lag) from mm:ss to hh:mm:ss

- Modified nest datatype (early/late) limit from 300' to 720'

- New independent nests function

- New aux 1 and 2 timer function

- Improved external humid climate management (possibility to set a negative delta)

- Improved nest relay management (1" wait on relay exchange)

- Improved 0-10v ventilation forcing management (active only if set for a time ->0v*1"+10v*T)

CHANGES from 1.31 to 1.32 of 15-09-2022

-Fixed bug generated in 1.31 on the display of "Females", "Males" and "Feed" on the Home page

CHANGES from 1.30 to 1.31 12-09-2022

- Correction of "Gr / Head of programmed water" display in the "Feeding Details" screen in the case of water at will

- Added possibility of excluding ampere and pressure alarms and cooling function in case of natural ventilation (double ventilation)

- Removed display of spare parts countdown in case they are excluded

- Changed data type of "set_avaria_flaps" (limit to 5:00 ')

- Changed bootstrap value of "set_avaria_flaps" (from 5:00 'to 2:00')

- Improved "flap movement" alarm management

CHANGES from 1.29 to 1.30 12-05-2022

- Fixed "maximum ventilation% step" block signal

- Correct value at boot for general NO / NC alarm contact

- Fixed fan-jet timing

- Added "Excluded" setting for the item weighing alarm

- Improved weight management (awaits confirmation on important changes)

- Improved peripheral connection (failure alarm after 16 failures)

- Improved data transfer to PC (silos unloading)

CHANGES from 1.28 to 1.29 14-01-2021

- Fixed total egg archive

- Added settings for general NO / NC alarm contact

- Limited minimum rotation settings to 1

- Improved data passage for cloud gateways

AMENDMENTS from 1.27 to 1.28 of 29-06-2020

- Modified nest opening / closing setting from min: sec to whole minutes (up to 300 ')

- Ventilation diff setting limit changed from 0.0 ° -30.0 ° to 0.2 ° -1.0 °

- Modified value at bootstrap of delta T sampling time from 5:00 'to 1.00'

- Alarm bootstrap value changed in (E-1-8-9) from "Display" to "Enabled"

- Fixed echo response from remote write (Error introduced in 1.24)

- Corrected stop ventilation with "set_memoria_parzializzazione_m3h = No" in the case set "Maximum ventilation" at the maximum step - 1 (the problem occurs at start-up or in the event of temperature fanning)

- Corrected silos loading totals

- Correct amperometric alarm with set ventilation delay

- Fixed vision of flaps set from 9 to 16

- Fixed 0-10v name table length to load on first bootstrap (48 to 64)

- Added manual relay page to drive up to 119

- Added bootstrap alarm

- Added German

- Arab language embryo

CHANGES from 1.26 to 1.27 09-04-2019

- Correct light output 0-10v (with lux) in fasting

- Fixed "heads = 0" message if ventilation only

- Added "Minimum maintenance" (E-2-4) to keep lights out of hours (turkeys)

- Added "Maximum speed% block" and "Maximum block% step number" (E-1-3-3-2-H) to limit 0-10v ventilation (with ramp)

- Russian added

CHANGES from 1.25 to 1.26 26-09-2018

- Modified operation of feeders for hens

- Improved cycle start with reset of any silos or medicated load in progress

- Correct ventilation rotation management (could rotate on a step greater than the set maximum)

- Correct password access management (showed an incomplete screen if you first accessed a locked setting - set calendar type)

- Amperometric alarm exclusion by setting "minimum absorption step x" to 0.0A

- Added warning "Attention: capi = 0"

- Added Portuguese

CHANGES from 1.24 to 1.25 16-03-2018

- Improved NH3 / CO2 exclusion management - display -1.0 / -1 in case of exclusion

- If select two LUX probes there are two 0-10v outputs and two independent minimum brightness alarms

- New management of feeders for hens

- Added lights relay off with reading lux> set + 1/2 dif and output = 0

- Added possibility of exclusion of 4-20mA humidity probes

- Modified value at boot of "Minimum brightness"

CHANGES from 1.23 to 1.24 18-01-2017

- Correct calculation 0-10v output lights during the descent ramp (with lights & lux)

- Improved 0-10v window management during air changes (timing) in m3 / h - (window is positioned at the set of the step calculated in ON and at the set of the previous step in OFF)

- Improved connection management with PC

- New possibility to assign the status of the "external alarm exclusion" contact to the optional alarm relays

- Added possibility of exclusion of CO2 / NH3 probes

- Added up mangers at the end of the fast

- Modified heating block delay time from 2 to 5 seconds

- Modified values at boot in Flap, Ventilation, Cooling, Alarms

CHANGES from 1.22 to 1.23 12-10-2017

- New light output with output 0-10v according to the luminosity probe (Lux), with the possibility of having up to two brightness probes.

- New display screen for luminosity probes

- New minimum luminosity alarm

- Added Calendars / Activation / Maximum Limit for 0-10V Light Management with luminosity Probe (Lux)

- Added step view inserted in the new "Table Info"

- Added reset flap in case of motion alarm

- Added ventilation set recording in daily archives (net pro)

- Added possibility to exclude cooling block for too much humidity (setting 100%)

- Modified data-type asc. and des. manger - Limit range from 10 'to 99' (maximum value in min: sec)

- Modified Power Calendar Values (Ross 308 curve)

- Added controls for Qfarm Net PRO with www.qfarm.cloud service

CHANGES from 1.21 to 1.22 10-05-2017

- New light management (only reading probe 0-10v on the first HXDA)

- New NH3 management (0-10v probe on HXNE)

- New screens Operating Tables Ventilation / Flap (Home> H> H> C)

CHANGES from 1.20 to 1.21 27-03-2017

- Fixed calculating water consumption at the end of the medicated (Archive_Day -> Days_Cycle)

- Fixed viewers Management (conn) -> Error introduced in 1:19 after modification for use with Qstorage

- Modified boot value of "Cycle Time spare parts" (E-1-3-2-1) to 600 "(10 ') to 300" (5')

CHANGES from 1.19 to 1.20 07-02-2017

- Fixed malfunctioning heating on/off in case of fan-jet enabling 0-10v

- Modified date-type "Display brightness" (E.2.4.D.3) (from +/- 80% to +/- 99%)

- Improved loading times by tables (erase)

- Added French language

CHANGES from 1.18 to 1.19 25-01-2017

- Updated RTC management to manage new CPU

- Updated spi-flash library to manage new chip

CHANGES from 1.17 to 1.18 29-09-2016

- Limited write eeprom remotely (only possible in the minimum / maximum range)

- Calculation using PC

- Improved read keyboard handling

- Updated USB host library - MSC

- Updated file system

CHANGES from 1.16 to 1.17 20-07-2016

- Increase the buffer size for USB handling filenames

- Improved management of external EEPROM (new chip Clock <10Mhz)

- Theoretical weight calculation feed curve to be used by PC

CHANGES from 1.15 to 1.16 24-05-2016

- Fixed EG GUI data type (signed)

- Improved schedules limit filter (related to the problem above)

CHANGES from 1.14 to 1.15 05-05-2016

- Fixed wrong access to the distribution screen if Qfarm ventilation only

- Fixed record date of the pre-boot cycle

- Fixed daily recording time igniting lights (was not saved at midnight)

- Fixed operating times power representation (problem if> 23:59)

- Fixed medicated delay minimum level sensor intervention

- Fixed zero external flash sectors to boot cycle (in the archives were correct only the first 255 days of the cycle)

- Fixed associative flap operation in air changes (minimum ventilation) in M3H and 0-10v

- Fixed CO2 graph

- New insight into the ventilation screen (countdown on and off of the air changes also M3h)

.png)

Our company has been developing automation systems since 1978 and now it can boast a highly skilled team of engineers for studying and developing the product right from the initial design stage to its final application. The experience acquired is intensively put into practice at all manufacturing stages to guarantee equipment performance and commitment to customer support. Close cooperation between R&D and production is essential to get the best from technical equipment design and application.

Our company has been developing automation systems since 1978 and now it can boast a highly skilled team of engineers for studying and developing the product right from the initial design stage to its final application. The experience acquired is intensively put into practice at all manufacturing stages to guarantee equipment performance and commitment to customer support. Close cooperation between R&D and production is essential to get the best from technical equipment design and application. Our production departments are fully automated to efficiently meet the various customers' requirements and guarantee proved standards with reduction of costs, which so far was only possible on a large-scale production.

Our production departments are fully automated to efficiently meet the various customers' requirements and guarantee proved standards with reduction of costs, which so far was only possible on a large-scale production.

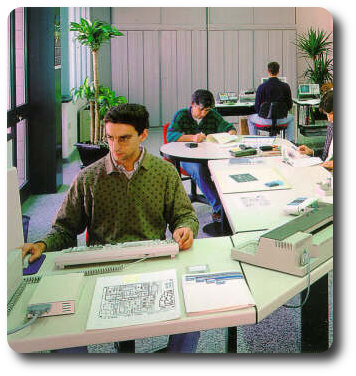

Advanced hardware design is the bedrock of our success with an intensive use of computer-based process automation systems right from the second half of the eighties, even in applicative fields which were considered “too poor” for computer science application.

Advanced hardware design is the bedrock of our success with an intensive use of computer-based process automation systems right from the second half of the eighties, even in applicative fields which were considered “too poor” for computer science application.  The range of products includes a few hundreds of standard models destined to various fields of process automation.

The range of products includes a few hundreds of standard models destined to various fields of process automation.  A data processing centre (EDP) linked in real time to internal user video terminals provides immediate handling of orders to ensure prompt deliveries.

A data processing centre (EDP) linked in real time to internal user video terminals provides immediate handling of orders to ensure prompt deliveries. Development of new products presupposes in-depth knowledge of the market situation and target range.

Development of new products presupposes in-depth knowledge of the market situation and target range.

COUNCIL DIRECTIVE 2007/43/EC of 28 June 2007 laying down minimum rules for the protection of chickens kept for meat production.

COUNCIL DIRECTIVE 2007/43/EC of 28 June 2007 laying down minimum rules for the protection of chickens kept for meat production.